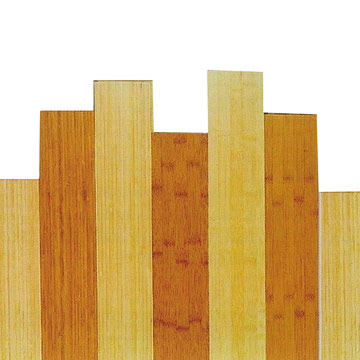

Bamboo is one of the most versatile and resilient materials out there with usage ranging from fashion, food, medicine and construction among others. From centuries of use, bamboo has continuously proven its reliability.

Perhaps the greatest selling point and the reason why more and more people prefer bamboo flooring is because it is both an environmentally friendly and highly sustainable material, however keep in mind that not all bamboo flooring are created equal. You may want to double check the manufacturing and delivery processes, if they comply with environmental standards.

Perhaps the greatest selling point and the reason why more and more people prefer bamboo flooring is because it is both an environmentally friendly and highly sustainable material, however keep in mind that not all bamboo flooring are created equal. You may want to double check the manufacturing and delivery processes, if they comply with environmental standards.

When you go out to buy bamboo flooring, be sure to add about 5-10 percent of the material to allow room for errors as well as spared should there be a need to replace some planks or boards in the future.

After the planks have been delivered, don’t get ahead of yourself and immediately install them. Get all the flooring materials in the room where they will be installed and lift them of the boxes or at least leave them open so that the planks can acclimate with the room’s natural conditions. The acclimation process is normally around 72 hours, but its best to see manufacturer’s instructions and follow that.

After the planks have been delivered, don’t get ahead of yourself and immediately install them. Get all the flooring materials in the room where they will be installed and lift them of the boxes or at least leave them open so that the planks can acclimate with the room’s natural conditions. The acclimation process is normally around 72 hours, but its best to see manufacturer’s instructions and follow that.

Subfloor:

Again, as with any flooring material, the success of your DIY installation project will largely depend on the subfloor’s preparation. Preparation will vary depending on the type of subfloor you have and the type of installation you have in mind.

In general, the subfloor must be level, structurally sound, clean and dry.

The level of the subfloor will affect not only the appearance of the bamboo flooring but also its durability. Its important to have a structurally sound subfloor to support the bamboo flooring. By structurally sound, we mean no squeaking floorboards or shaky joists. All repairs must be done before flooring planks are attached. The subfloor must be pristinely clean, thoroughly swept free from nails, staples or adhesive residue. Lastly and most important, the subfloor must be dry with a recommended room temperature of 60-70º and a humidity of about 40-60%.

The level of the subfloor will affect not only the appearance of the bamboo flooring but also its durability. Its important to have a structurally sound subfloor to support the bamboo flooring. By structurally sound, we mean no squeaking floorboards or shaky joists. All repairs must be done before flooring planks are attached. The subfloor must be pristinely clean, thoroughly swept free from nails, staples or adhesive residue. Lastly and most important, the subfloor must be dry with a recommended room temperature of 60-70º and a humidity of about 40-60%.

Tools:

The following tools will be needed for a DIY bamboo flooring installation:

- measuring tape

- hand saw or power saw

- tapping block

- wood or plastic spacers

- pry bar

- hammer

- chalk line

- pencil

- recommended underlayment/moisture barrier

- bamboo flooring

As we mentioned earlier, there are several ways to install bamboo flooring and these types of installations will require different tools:

- Nailed-down Installation – for this type you’ll also need:

- the appropriate nailer/nail gun

- nail application chart

- Glued-down Installation – for this type, we need:

- recommended flooring adhesive

- trowel

- pail, optional for mixing adhesive

- Floating Installation –

- poly film foam or other manufacturer recommended product

- PVAC glue

- poly or duct tape

Some Final Pre-installation Reminders:

- Be sure to remove existing trims, mouldings and baseboards to the room.

- Also trim doorways, door and passage ways

- Remember to examine each piece of flooring for defects and use planks from different boxes to give a unique look.

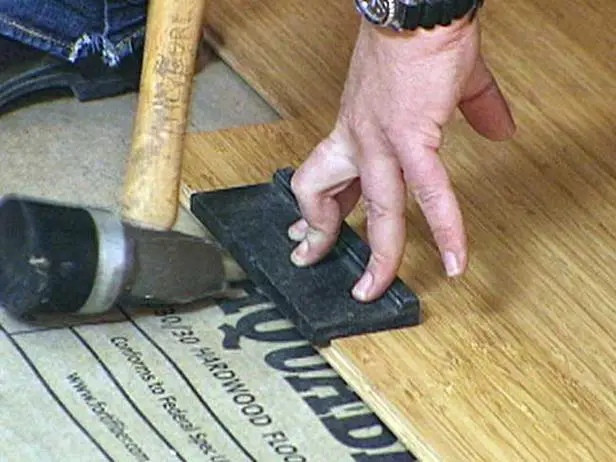

- Remember to use the tapping block to securely lock each plank and gently pull with a pry bar.

- Begin on the longest side of the room and continue on that line.

- Remember to keep allowance for expansion.